Fastest

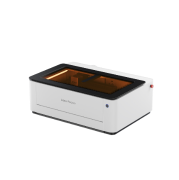

Enclosed Production

35% Faster: How?

The Reliable Path to Growth

Cut Deeper,

Faster with 40W

Unrivaled

Single-Pass Depth

Throughput Maximized

Edge-to-Edge Precision

Smart Air Assist

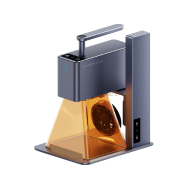

Customize Your Power

Tool-Free, Modular Swap

Dual-System Positioning

Point-to-Shape™ Positioning

Camera Positioning

From

Space-Saving to

High-Volume

Space-Efficient Design

Accessories for Expanded Capability

Any Surface,

Flawless

Engraving

3D Adaptive Focus

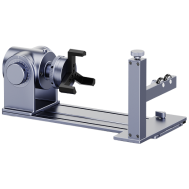

Rotary Extension

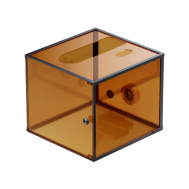

Pro-Grade Active Safety

Total Protection, Built-In

Accessories for Maximum Safety

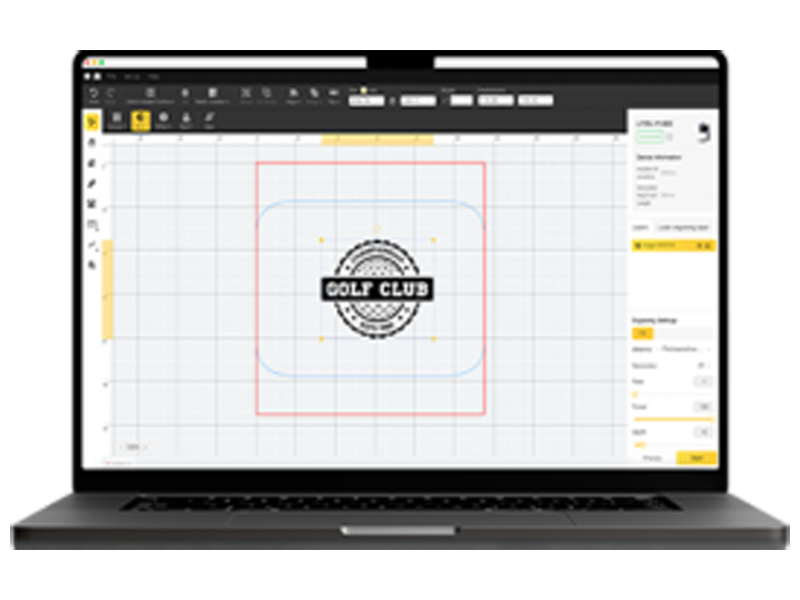

LaserPecker

Design Space Beta

Compatible with LightBurn

Smart Material Library

Instant Puzzle Creator

Cable (1.5 m) × 1 Cable 1.5m x 1 / 0.6m x 1

User Manual x 1

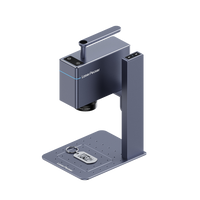

20W Diode Laser: 114 mm × 77.4 mm × 72 mm

40W Diode Laser: 152.2 mm × 77.4 mm × 72 mm

2W Diode Laser: 135 mm × 72 mm × 65 mm

· 20W Diode Laser: 554 g

· 40W Diode Laser: 766 g

· 2W IR Laser: 750 g

· 40W Diode Laser

· 60W Diode Laser (coming soon)

· 2W Infrared Laser

· Up to 19 mm Cherry wood

· Up to 20 mm Acrylic

· Up to 0.5 mm Stainless steel

· With Optional Riser Base: Ø150 mm

(Requires installation of the optional riser base)